Finse Oy is a family-owned metal industry company founded in 1989. We have grown from a small Central Finnish workshop into an international OEM-supplier. We specialize in heavy-duty tube components such as exhaust, water, air, and protective piping. We deliver all components installation-ready directly to our customers’ assembly lines. Our factories are located in Lievestuore, Central Finland, with a total of 4,000 m² of modern production space and a team of 50 industry professionals.

Our strength lies in advanced tube bending and metal forming expertise combined with modern production methods. The components we manufacture are used in vehicles and machinery produced by Valtra, Proventia, Sandvik, and several other globally operating OEM-manufacturers.

Our operations are built on long-term partnerships, documented quality, and responsible production. We are certified according to ISO 9001:2015, ISO 14001:2015, and ISO 3834-2, and we are committed to continuously improving our processes, working environment, and environmental responsibility.

History

1989

Lievestuoreen Metallimiehet Oy was founded in Lievestuore, Central Finland.

1991

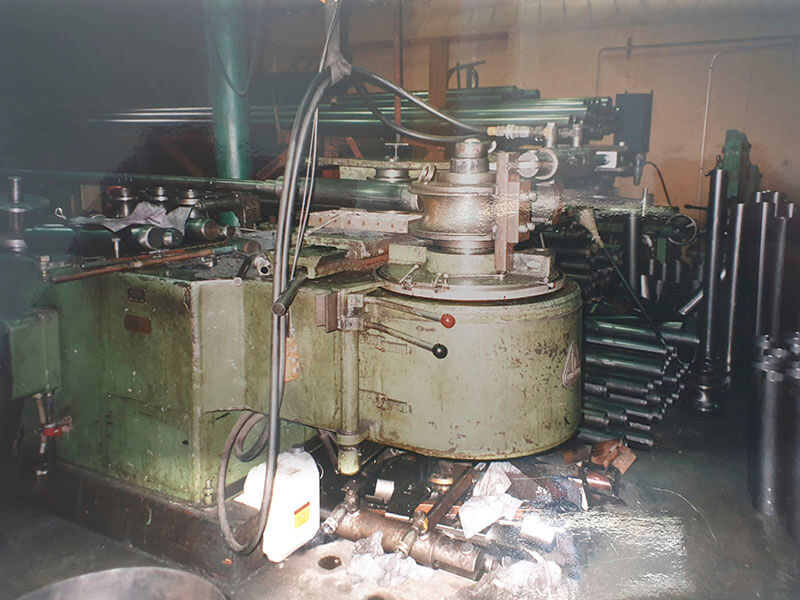

Lievestuoreen Metallimiehet Oy was acquired by Pertti Hyppönen. Production was directed toward manufacturing piping systems, silencers, and fuel tanks. The main customers were the manufacturer of Finnish SISU-trucks and several spare-part distributors. Operations continued in the original 300 m² facilities with a team of four people.

1995

1996

2000

2002

2003

Our name was changed from Lievestuoreen Metallimiehet Oy to Finse Oy. The new international name supported our goal to expand our operations into the international OEM-markets.

2005

2006

2008

We began our cooperation with Proventia in the manufacturing of exhaust aftertreatment systems — a significant new customer for us.

2010

2012

2015

2017

The largest facility expansion in our history to date. We purchased a modern 2,100 m² hall located along Highway 9. In addition to our own production, the premises also house Jyväs Pakari’s café, shop, and lunch restaurant as tenants.

2018

Our production was divided between two locations, and we invested in a second laser cutting machine to increase production capacity.

2019

2022

We invested in new bending technology by acquiring our first fully electric AMOB 150 eMOB bending machine, further improving precision and efficiency.

2025

Quality Is the Result of a Structured Process

Our production process is designed to support the customer’s own product development and to ensure that every component can be manufactured accurately, repeatably, and cost-effectively. The process covers everything from the early design phase to PPAP analysis and serial production — combining technical expertise, quality systems, and strong project management.