We are a service partner for OEM-manufacturers of off-road equipment. As part of our portfolio, we also support heavy-duty combustion engine solutions for demanding industrial applications. In addition, we provide robust piping solutions tailored to the specific needs of the agricultural sector.

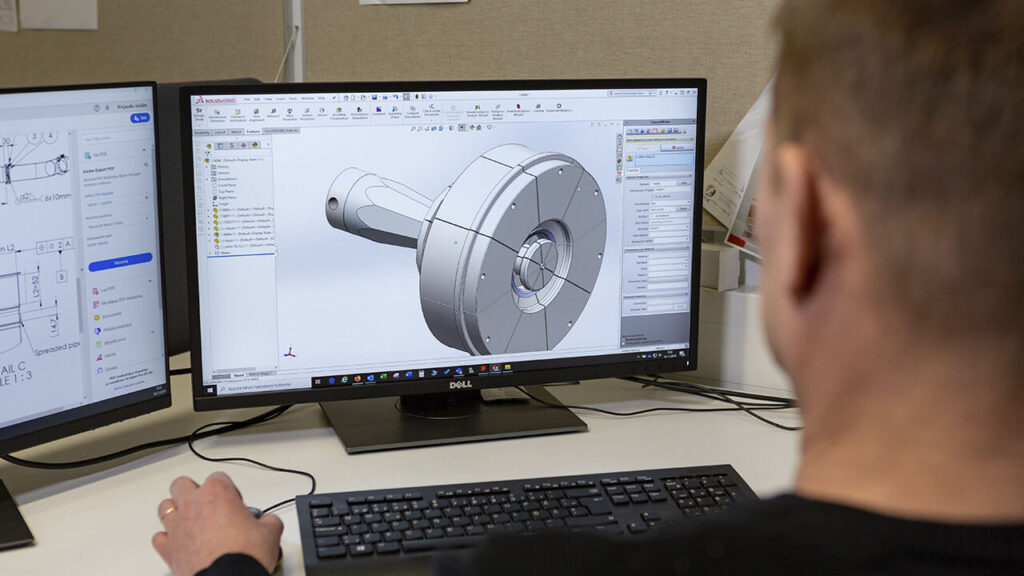

Our core competencies include tube bending and cutting, pipe thermal insulation, muffler manufacturing, exhaust aftertreatment system production for heavy-duty combustion engines, fuel tank manufacturing, as well as CAD-based product development and tooling. We also process sheet metal with 2D and 3D cutting technologies, complemented when needed by press brakes and CNC-rollers capable of producing variable-radius components.

Our expertise serves international OEM-suppliers specializing in earthmoving, forestry, agricultural, mining, and material-handling machinery, as well as special-purpose vehicles.

Our long-term international OEM-customers include AGCO, Sandvik, Proventia, Ponsse, and John Deere. They expect production-line accuracy, flawless quality, and process reliability from every delivery.

For more than 30 years, we have supplied hundreds of thousands of components and various tube assemblies for heavy-duty applications.

1. Request for Quotation

2. Technical Review

3. Sample

4. Quotation

5. Tooling Design and Manufacturing

6. Prototype Parts and PPAP-Analysis

1. Request for Quotation

The more information we have available at the early stage, the better we can optimize the structures, materials, and production methods, and provide a more accurate cost estimate.

Our strength lies in our ability and long-standing experience in combining design and production expertise. The earlier we become involved in the design process of a new product, the more optimized and cost-efficient the final outcome will be.

Our specialists can contribute to the project at any stage of the design process:

Early design phase

We help identify, which structures, materials, and tube components best support the product’s functionality and assembly.

Drawing phase

We provide manufacturing-oriented insights and ensure that the designed structure can be produced efficiently and within required tolerances.

When working with finalized designs

We perform a manufacturability analysis and propose improvements that help save time and reduce costs on the production line.

To prepare an accurate quotation, we typically require:

Drawings or 3D models (e.g., STEP, DWG, or PDF format)

A description of the product’s application and functional requirements (e.g., flow, temperature, vibration, pressure)

Material specifications and any possible alternatives

Tolerance requirements and critical dimensional points

An estimate of the required production volume (prototype / small series / mass production)

Any quality standards and certifications required in the customer’s production (e.g., ISO, IATF, PPAP level)

The desired delivery schedule or overall project timeline

2. Technical Review

During the review, we assess the product’s manufacturability, technical limitations, and potential optimization opportunities before moving on to tooling design.

The purpose of the technical review is to ensure that the designed product can be manufactured consistently and cost-effectively. At the same time, we identify potential risks—such as material selection, bending radii, joint solutions, and critical tolerances—before moving on to tooling production.

During the review, the product structure is optimized so that it fits smoothly into the assembly process and performs reliably in use. All findings and recommendations are documented transparently for the customer, enabling fact-based decision-making and ensuring that the project proceeds in a controlled manner to the next phase.

As part of the review, we may propose:

Modifications to the geometry of tube bends or joints

Alternative material thicknesses or material grades

Improvements to welding and attachment points

A completely new approach to implementing the product, if it provides a significant benefit to manufacturability and overall cost.

3. Sample

Once the technical review has been completed and manufacturability confirmed, we proceed to creating the sample and drawing.

With the sample, we take the solution, i.e., the new product, from theory into practice. Every tube bend, joint, and dimension is designed to ensure that the product operates reliably and can be installed smoothly in the customer’s assembly process. We finalize the drawings according to our internal production standards and deliver them to the customer for review.

The customer approves the model before we proceed to tooling design. This phase ensures that the solution meets all functional, quality, and production requirements. The approved sample serves as the basis for tooling, prototype parts, and ultimately for serial production.

Key points of the modeling phase

Modeling

Our design team models the product accurately based on the customer-approved specifications.

Manufacturability

Production standards

Approval

We deliver the sample and drawings to the customer for review and feedback.

Revisions

4. Quotation

We make the quotation process transparent, smooth, and reliable for the customer. Our quotation is structured so that every cost and work phase is clearly presented. We ensure that the customer fully understands what we are offering and that it aligns with their request and requirements. We provide a complete manufacturing solution designed with the product’s lifecycle and assembly in mind.

At the same time, the quotation serves as a technical roadmap for the entire project. It outlines how production will start and on which schedule, which documentation is included in the delivery, and how quickly we can supply the first parts to the customer’s production line.

Our goal is always to provide a clear and comprehensible quotation that supports and speeds up the customer’s decision-making process.

Our quotation includes:

Design and manufacturing of the required tooling

Production of prototype parts for customer approval

PPAP analysis at the level required by the customer

A clear schedule for the start of production and deliveries

Defined quality assurance and documentation requirements

Recommendations for production optimization for future batch sizes or serial manufacturing

5. Tooling Design and Manufacturing

Our in-house design team is responsible for developing and manufacturing the tooling solutions. When needed, we also utilize our carefully selected partner network—such as specialized tool manufacturers and machining services—to ensure that every detail is executed as efficiently and with as high quality as possible.

Tools such as bending dies, welding jigs, and measurement fixtures are always designed specifically for each customer. Every tool is dimensioned and documented to ensure consistent production quality and smooth quality assurance during ongoing manufacturing.

For the customer, this means:

A fast and predictable transition from design to serial production

Reliable quality from the very first delivery

Minimal need for changes and shorter lead times in their own production

Cost-efficient and stable manufacturing

Our tooling design process:

Customization

Manufacturing and Testing

Documentation

Adjustments

When necessary, we modify the tools, dies, jigs, etc., before serial production begins.

Durability

We use durable materials in our tools and maintain them regularly to ensure long-term reliability.

6. Prototype Parts and PPAP-Analysis

Before serial production begins, we manufacture prototype parts that allow the customer to see and test the product’s functionality in practice.

The prototype parts provide concrete proof that the design, tooling, and manufacturing methods work together exactly as agreed.

Our team ensures that the prototype parts fully match the approved sample and meet all of the customer’s technical, functional, and visual requirements. Based on these prototypes, the customer gives final approval before serial production begins.

We perform the PPAP analysis (Production Part Approval Process) at the level required by the customer. This analysis verifies that the manufacturing process is under control, dimensional accuracy stays within tolerance, and quality is repeatable from one production batch to the next.

With the prototype parts and PPAP analysis:

Both we and the customer gain confidence that the final product fully meets expectations

Documentation of product quality and the manufacturing process is transparent

The transition to serial production is smooth and reliable

Approval is fast, enabling a seamless start-up in production

What is a PPAP Analysis?

PPAP (Production Part Approval Process) is a standardized quality assurance procedure widely used in the automotive industry and OEM manufacturing. Its purpose is to ensure that the product design and the manufacturing process consistently produce parts that meet all of the customer’s quality and performance requirements.

Our PPAP analysis ensures that:

Our production can manufacture the parts within the required tolerances

The customer’s production operates smoothly and without issues

Every production batch is traceable and fully documented

Any potential risks or deviations are identified and corrected before serial production

The customer’s quality and documentation requirements are met (e.g., PPAP Levels 1–5)

Precision and Traceability

Fast Response

Assembly-Ready Components

30 Years of OEM Experience

Over 30 years of collaboration with international manufacturers.