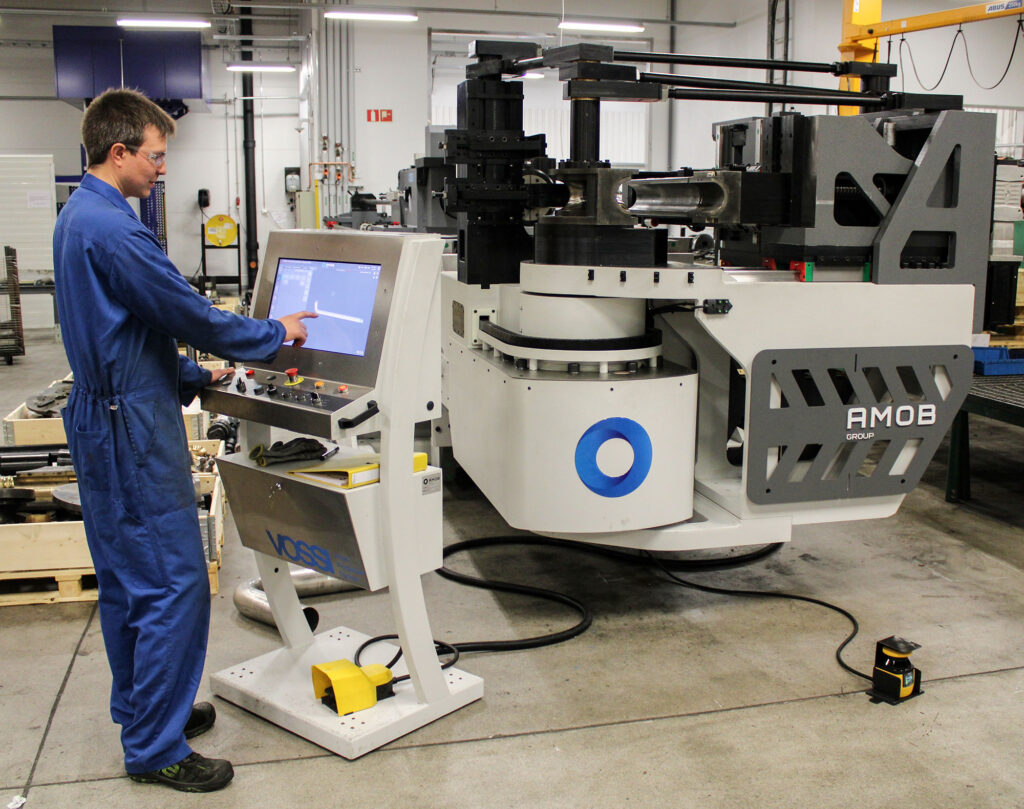

Finse’s new AMOB 150 CNC tube bending machine can bend tubes with a diameter of up to 154 millimetres. It also enables even tighter bends. For example, tubes with a diameter of less than 140 millimetres can be bent so the radius is the same as the diameter, such as 130 degrees.

“Customers have a need for larger tubes and tighter bends. For example, exhaust pipes and exhaust gas treatment systems for larger engines are often packed into increasingly smaller spaces, requiring tighter bends as a result,” explains Finse CEO Antti Hyppönen.

The fully servo tube bending machine can bend both traditional black steel and stainless steel with a wall thickness up to 2 millimetres.

The new AMOB 150 CNC will be used alongside Finse’s two older tube bending machines, increasing capacity significantly. The new machine not only expands Finse’s offerings and capacity, it is also extremely precise, energy efficient, fast and safe to use.